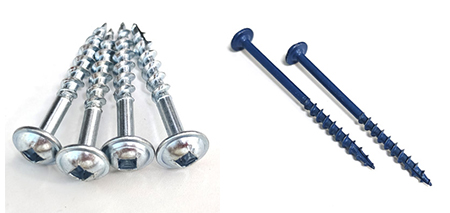

Made of C1022A low carbon steel, these screws feature a blue Ruspert anti-corrosion coating that withstands 48–500 hours of salt spray testing. Designed primarily for wood-to-wood connections, they are often used as pocket screws or pocket hole screws in cabinetry and furniture assembly.

The washer head provides a larger bearing surface to prevent pull-through, while the square drive (Robertson) design ensures higher torque transmission and minimizes the risk of cam-out or stripping.

If you have any requirements or inquiries, please feel free to contact us anytime.

Correct screw length is based on the thickness of materials.

| Material thickness | 1/2" | 5/8" | 3/4" | 7/8" | 1" | 1-1/8" | 1-1/4" | 1-3/8" | 1-1/2" | |

| Screw Length | 3/4" | 1" | 1" | 1-1/4" | 1-1/2" | 1-1/2" | 1-1/2" | 2" | 2" | 2-1/2" |

Coarse-thread screws are ideal for plywood and medium-density fiberboard (MDF). The coarse threads bite deeply into these softer fibers, providing a strong hold.

Fine-thread screws are recommended for high-density, harder woods. Since fine threads are narrower and more numerous, they deliver stronger fastening power while reducing the risk of splitting the wood fibers.

Softwoods include: pine, cedar, fir, spruce, poplar, aspen, basswood, butternut, plywood, particle board, MDF, and melamine.

Hardwoods include: oak, maple, cherry, birch, ash, walnut, mahogany, and hickory.

Surface Treatments:

Zinc Plating: Suitable for indoor projects. Zinc-plated screws are commonly used in kitchens and bathrooms.

Blue Ruspert Coating: Designed for damp or humid environments. The blue Ruspert surface treatment provides excellent corrosion resistance in moisture-prone areas.